Stay In The Loop!

Compliance Guide

Version 13 – 2023

Our Compliance Guide provides a quick reference and highlights the regulation responsibilities required of certified stakeholders. It provides an overview of the various program partners or players, such as RMC, UNEP and enforcement contacts.

If you see anything we’ve missed, or anything that needs clarification, please send us your feedback to mopia@mopia.ca

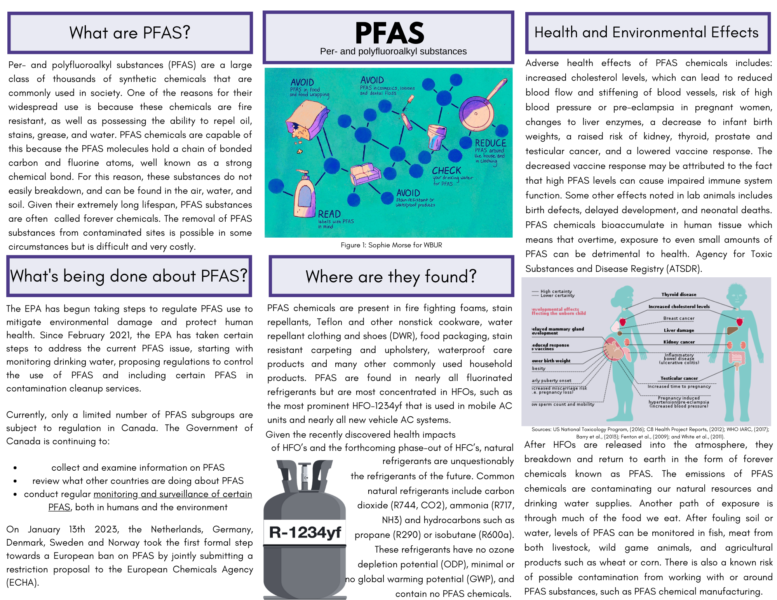

PFAS Bulletin

Version 1 – 2023

Our PFAS Bulletin highlights some of the most pressing and important issues with the use of PFAS substances. The PFAS bulletin provides technicians with an overview of the environmental and human health impacts caused by these harmful substances.

If you see anything we’ve missed, or anything that needs clarification, please send us your feedback to mopia@mopia.ca

A/C Purchasing Bulletin

Only Certified technicians who hold a valid certification card may purchase regulated refrigerants and parts along with companies in Manitoba that hold a Secondary Distributor permit. Wholesalers and anyone selling regulated products must see/record the certification number or SD Permit number of each regulated item they are selling. Penalties for not doing so are up to $500,000 on a first offence.

MOPIA’s 31st Annual Report

November 1, 2023 – October 31, 2024

We’re excited to share that MOPIA recently held its Annual General Meeting, marking a year of meaningful progress and collaboration in environmental stewardship. As part of our commitment to transparency and engagement, we’ve published our 31st Annual Report, now available for public viewing.

Inside, you’ll find insights into our initiatives, key achievements, and the strategic direction we’re taking for the future. Whether you’re a stakeholder, partner, or simply curious about our work, the report offers a comprehensive look at what we’ve accomplished — and what’s ahead.

Industries

Halon Working Group

Manitoba’s Halon Working Group was first established in April, 1994. An education certification sub committee successfully oversaw and developed Canada’s first halon environmental training course as part of MOPIA’s commitment to meet the certification training requirements as per the ODS regulation. The working group also successfully recommended changes to the Manitoba Fire Code to complement and harmonize provincial legislation.

MOPIA actively participates on the National Halon Round Table, a federal government sponsored working group of industry representatives. Since provincial governments are not participants at the Round Table meetings, MOPIA provides the leadership and voice of concerns for Manitobans.

MOPIA has produced a short municipal bulletin, which provides suggested or best practices for proper management of halocarbon containing appliances (i.e. refrigerators with chlorofluorocarons [CFCs] or alternative substances). The main focus of this bulletin is to assist and educate municipalities within Manitoba towards the proper recovery of refrigerant (Freon) from discarded appliances. In addition, it may also help to establish certain aspects of a municipal management strategy including estimating the appliance waste stream in a community; facilitating partnerships between municipal councils and certified refrigerant contractors; and helping with the promotion of a municipal halocarbon recovery program.

Residents are reminded to check with their municipal officials regarding policies towards disposing of unwanted appliances containing refrigerants – as requirements differ between jurisdictions. Municipal officials are also reminded that refrigerants must be recovered prior to an appliance being recycled or crushed. Please contact MOPIA for a list of reputable certified contractors near you.

Chillers containing CFC’s are required by law to be registered with MOPIA. Upon registration with MOPIA the chiller will be issued a working permit, which allows certified technicians to perform work on the Chiller.

This permit enables MOPIA to track the number of operational, converted, and decommissioned chillers in the province. This information also gives MOPIA a representation of how much CFC refrigerant is in use in the province.

To register a chiller, complete the application on the Forms page, and return it to MOPIA.

Fixed Fire Extinguishing Systems

Any FFE system is required by law to be registered with MOPIA. Upon registration, the FFE system will be issued a permit. These permits allow MOPIA to track halon use within the province.

To register a FFE, complete the application on the Forms page, and return it to MOPIA.

Nine Manitoba hospitals (seven Winnipeg and two rural) were monitored in their transition away from 12/88 ethylene oxide. Through the support of the Urban Shared Services Corporation, 100% Ethylene Oxide was the alternative of choice for past ODS sterilant practices.

More information to come

Leak Testing

You must eliminate the practice of venting any regulated refrigerant. In addition, it is mandatory to leak test by not adding any regulated refrigerant(s), including all ozone depleting and most climate change designated refrigerants (see Manitoba Ozone Depleting Substances and Other Halocarbon Regulation – MR 103/94 for the designated list). It is common industry standard to use nitrogen and/or soap & water. Other methods are acceptable (see below).

Please note that it is also good practice to recover un-regulated refrigerants. Some of these substances are potentially harmful as greenhouse gases and/or may be harmful to human health or the environment.

Separate recovery units are required to contain different refrigerants. Cross contamination of refrigerant gases may cause air conditioning equipment damage if it is replaced in a unit. Mixing of refrigerants is contrary to the Regulation.

Under the Manitoba Regulation 103/94, no person shall recharge or top-up equipment that contains an ozone depleting substance (ODS) unless the person first conducts a leak test and repairs the identified leak permanently. Technicians may choose one or more of the following leak test methods to ensure a units system is/will work effectively after any ODS is added following the system’s repair. The following is the prescribed leak test procedure and list of acceptable leak testing methods recognized by Manitoba Environment. They are subject to change.

- If the system still contains a regulated refrigerant, proceed to #3.

- If the system has lost its charge and no longer contains an regulated refrigerant, it must fist be pressurized to a minimum of 150 psi (1034 kPa) or such a pressure as not to rupture the system using dry nitrogen.

- Use one of the appropriate method(s) indicated under “Acceptable Leak Testing Methods” to detect the presence and location of the leak(s).

- If no leak is detected after fully and thoroughly leak checking, you may recharge the system with the appropriate or manufacturer designated refrigerant.

- If a leak is found, isolate that component(s), if possible. Recover any refrigerant from the component or system.

- Once any remaining refrigerant has been recovered, repair or replace the component or system.

- Perform another leak test method to confirm that the leak has been repaired. If any leaks are found, repeat #1-7 until all leak(s) have been repaired.

- Evacuate the system in accordance with the manufacturer’s recommended evacuation/dehydration levels. When the manufacturer’s information is unavailable evacuate to 29.87 in Hg. (550 microns) and hold for a minimum of 10 minutes (as described in the “Acceptable Leak Testing Methods” Standing Vacuum Test).

- The system has now been evacuated and dehydrated. The system must now be recharged using the accordance with the Manufacturers Certified Installation, Specifications and Service Manuals and the Environmental Code of Practice for the Elimination of Fluorocarbon Emissions from Refrigeration and Air Conditioning Systems (published by Environment Canada). These items are subject to the Minister’s approval and amending and updating.

- An ozone depleting substance (i.e. HCFC-22, HFC 134a or any other) must not be added to nitrogen or dry air for use as a trace gas. However, you may use the remaining (remnant) gas that was in the system to immediately check for leaks.

There are many different techniques for leak testing, with varying degrees of accuracy depending on the system being tested. The following guidelines are acceptable procedure for leak testing on various stationary refrigeration and air conditioning systems.

The following techniques have been identified by MOPIA and are acceptable by the Minister of Conservation. The most appropriate leak test method for the circumstance should be chosen and performed by a Manitoba certified individual (“trained service technician”). The completing of a leak test is not a guarantee against leaks in the future, and therefore is not meant to replace any existing preventative maintenance program.

1. Electronic leak detection

2. Halide flame leak detection

3. Soap and bubble test

4. Ultrasonic leak detection

5. Fluorescent dye leak detection

6. Standing Vacuum test

7. Standing nitrogen pressure test

Note: Any additional leak testing technologies that are developed and find acceptance within the refrigeration and air conditioning industry may become acceptable and added to these guidelines. They must first be approved by the Minister of Conservation. It is recommended that you periodically check with MOPIA for the latest list of acceptable leak test procedures.

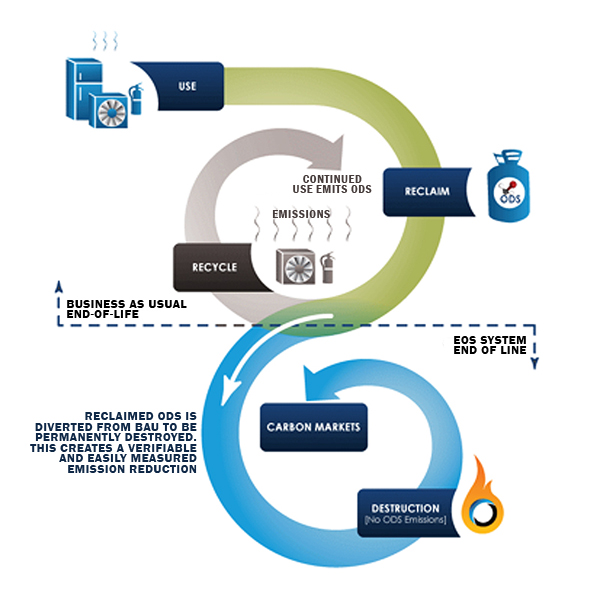

Refrigerant Disposal

Refrigerant Management Canada (RMC) in partnership with various refrigerant manufacturers and wholesalers are engaged in the safe disposal of certain surplus refrigerants (i.e. CFC’s, HCFC’s) in Canada, including Manitoba.

Visit RMC’s website for details at:

Transitional Training Solutions to Climate Friendly Refrigerants

Recycling and Solid Waste in Manitoba

Check out Manitoba’s WasteWise website for eco-depot locations, compost information, recycling directory, and solid waste sites close to you, or sorted by municipal boundaries!

"WasteWise is a hub for people and industries to get information about waste reduction options in Manitoba."

View the WasteWise homepage here:

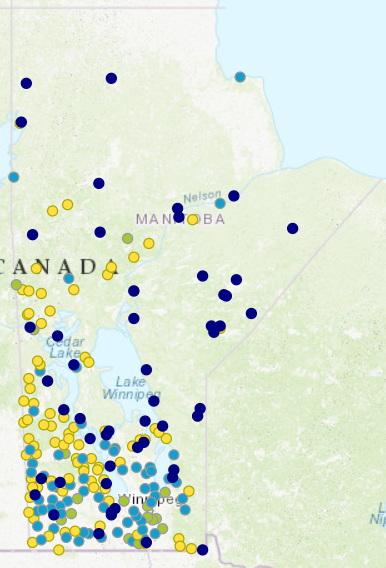

View the interactive landfill map here:

Depot sites across Manitoba:

Refrigerative Supply

1095 Erin Street,

Winnipeg, Manitoba R3G 2X1

Phone: (204) 775-5887

Toll Free: 1-800-665-1255

Website: www.rsl.ca

Trane

9-2061 Logan Avenue

Winnipeg, Manitoba R2R 0J1

Phone: (204) 632-1543

Website: www.trane.com/canada

Independent Supply Co Inc

Unit A – 1791 Dublin Avenue

Winnipeg, Manitoba R3H 1A9

Phone: (204) 694-4606

Toll Free: 1-844-694-4606

Website: www.isc.tv

WWG Totaline

1725 St. James, Unit 7

Winnipeg, Manitoba R3H 1H3

Phone: (204) 775-2523

Website: http://wwgtotaline.ca

Wolseley Canada Inc.

1365 Erin Street

Winnipeg, Manitoba R3C 2T8

Phone: (204) 775-9731

Website: www.wolseleyinc.ca

EMCO Corporation

Emco/Wholesale Heating Brandon

2150 Park Ave, Brandon , Manitoba R7B 0R9

Phone: (204) 726-8202

Website: www.wholesaleheating.ca/

Penalties & Fines

All compliance related penalties are defined under the Manitoba Ozone Depleting Substances Act and you will see they can be significant for persons contravening the Regulation.

Manitoba Environment, Climate and Parks’ Environment Officers enforce the Regulation. Any tips or non-compliance or any concerns with enforcement should be directed to your local office of Manitoba Environment, Climate and Parks – we plan on listing these contacts here soon.

In addition, any compliance related concern at Federal facilities should be directed to Environment Canada’s Environment Officers.